VERTICAL FARMING

IDEA

The world is facing increasing food scarcity and food supply challenges that are being exacerbated by climate change and a growing population.

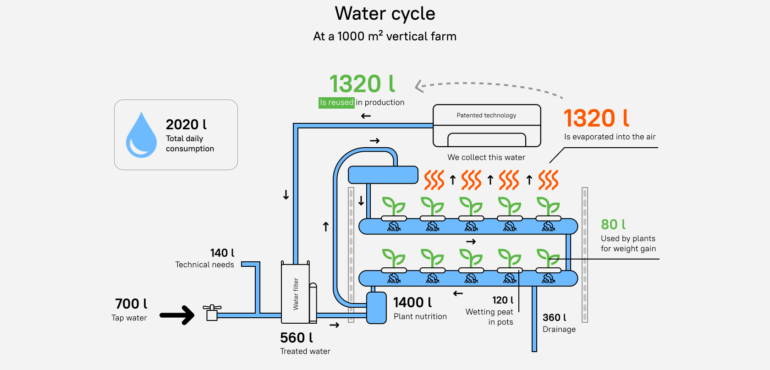

A potential solution to this problem exists in Vertical Farming (VF), which can produce a 10 to 20-fold greater yield per acre than traditional farms, whilst using up to 95% less water.

The global Vertical Farming is currently worth $5.5B. With current growth at 24.6% per annum it is expected to reach $12.77B by 2026.

We have experienced agronomists and engineers on our team and we have collaboration agreements with

We believe that our product will be a game-changer within the rapidly expanding Vertical Farming industry and we invite you to join us on this journey to a more sustainable future.

Our Story

•Founded in 2017, the company specialises in Agritech and Advanced Manufacturing solutions using innovative modular technology.

•We have raised over £2.4M in funding so far.

•We have a research unit for the enhancement of the innovative GBS Eco Panel, a structural insulated panel (SIP) which is integral to the construction of our vertical farm units.

•Collaborations with Worldfresh, one of the world’s largest suppliers of fresh produce, as well as GE Current, a Daintree Company, US.

Mission

•We aim to address the UK’s post-pandemic food supply challenges and become the leading manufacturer of low-cost hi-tech bespoke vertical farms for the hospitality and retail sectors in the UK and worldwide.

A World Wide Distributor Of Vertical Farms

We Are Ready For Vertical Farms,

All We Need Is To Use It Well!

$

1

b

Global Vertical Farming is currently worth

1

%

Current growth per annum

$

1

b

Expected to reach at 2026

The new Futura Led lamp is ideal for vertical farm cultivation. Its full spectrum in PAR allows you to get the most out of your harvest in both quantitative and qualitative terms.

Thanks to the broad spectrum and the dimmability of the luminous flux, it is possible to grow any type of vegetable in microgreens, baby leaves and aromatic essences.

Thanks to its lightweight design and ease of installation in series with the practical connectors at the end, the Futura lamp can be installed close to plants for better photosynthetic efficiency and also implanted in confined spaces, typical of vertical farm cultivation.

Furthermore, the degree of protection IP65 guarantees operation even in humid environments.

Vertical farming is the practice of growing crops in vertically stacked layers. It

Growing Software is your guide to growing the day-to-day challenges of running a

Growing Software is your guide to growing the day-to-day challenges of running a

A world wide destributor of vertical farms

How do we

grow it

grow it

In recent years, new capacity across the solar value chain has become necessary to support the PV market’s growth. However, the capital required to establish and scale-up wafer, solar cell and solar module manufacturing facilities is considerable.

In recent years, new capacity across the solar value chain has become necessary to support the PV market’s growth. However, the capital required to establish and scale-up wafer, solar cell and solar module manufacturing facilities is considerable.

Software

In recent years, new capacity across the solar value chain has become necessary to support the PV market’s growth. However, the capital required to establish and scale-up wafer, solar cell and solar module manufacturing facilities is considerable.

Consumables

In recent years, new capacity across the solar value chain has become necessary to support the PV market’s growth. However, the capital required to establish and scale-up wafer, solar cell and solar module manufacturing facilities is considerable.

Growing method

In recent years, new capacity across the solar value chain has become necessary to support the PV market’s growth. However, the capital required to establish and scale-up wafer, solar cell and solar module manufacturing facilities is considerable.

Improving The Performance Of Solar Energy.

Latest Projects, Solutions And Energy Supplies

With our innovative technologies, clear focus on the needs of our customers, and 1,210 dedicated employees, we energize society. Let’s make tomorrow different today!

All Projects

Customers Doing it Their Way

Our Customers Share Their Experiences & Insights

Solatec has been absolutely the best to work with. Their attention to detail and customer support was amazing!!

Solatec has been absolutely the best to work with. Their attention to detail and customer support was amazing!!

Solatec has been absolutely the best to work with. Their attention to detail and customer support was amazing!!

Solatec has been absolutely the best to work with. Their attention to detail and customer support was amazing!!

Solatec has been absolutely the best to work with. Their attention to detail and customer support was amazing!!

Design & Shipping

We collaborate with you to design and deliver a system that meets your utility usage and selecting equipments.

Contract & Install

Whether you want to install the system on your own or hire local contractors directly managing the installation.

Discover independence through the power of solar,

Explore Our Plans

Save Money, Save The Environment!

Providing Value To Our ClientsThrough Ongoing Product & Innovation.

Our Solar business now provides the preferred channel to market for some of the world’s leading PV manufacturers and our solar professionals work jointly with partners on enhancing product features, lowering lead times and improving cash flow.

Environmental Sensitivity

Personalised Solutions

Performance Measures

Request A Quote

Receive an accurate quote within 3-5 days when you fill out the form on this page. Or, give us a call:

(002) 01061245741

News & Announcements

Recent Articles

December 8, 2020

gsc.admin

All of these factors are important to consider when permitting your solar system, and can help streamline your process. Take the time to consider these...

December 8, 2020

gsc.admin

Batteries are the most expensive part of a solar system. Between an appropriately-size battery bank and a battery-based

December 8, 2020

gsc.admin

Department of Energy, which is why we have funded six teams to improve technologies that will protect eagles sharing airspace with the new wind turbines

Quick Contact

If you have any questions or need help, feel free to contact with our team.

2307 Beverley Rd Brooklyn, New York 11226 United States.

Home

About us

Contacts & information

©2022 Solatec, All Rights Reserved.